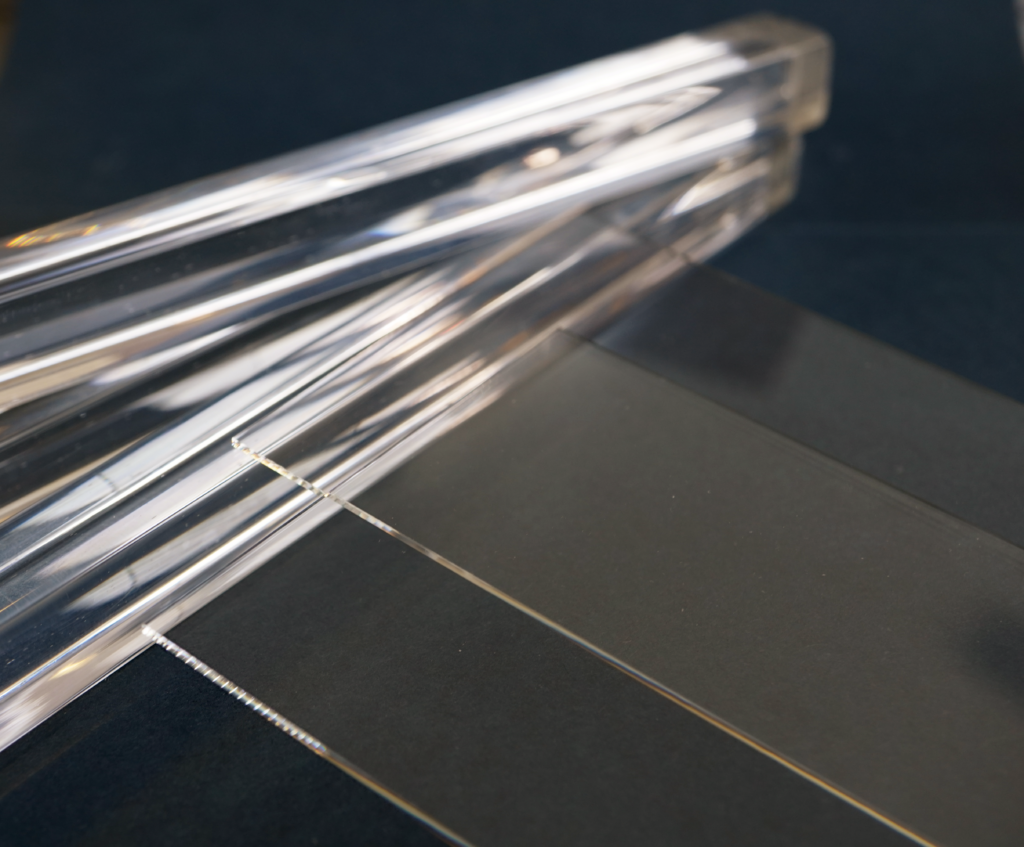

Optical and technical glasses

Glass is one of the oldest materials known to mankind and has become an indispensable part of countless industries. Our offer includes precise glass processing of a wide variety of materials. Below you will find a selection of the classic types of glass and their properties.

In addition, we offer processing of other glass materials such as sapphire glass, calcium fluride.

If you should desire another ceramic material, then please send us a Request.

Material properties

| Properties | SCHOTT NBK-7® | |||

|---|---|---|---|---|

Density p [gcm3] | 2,2 | 2,5 | 2,5 | 2,2 |

Coefficient of expansion a (20°C – 300°C) [1*10-6/K] | 3,3 | 8,3 | 2,2 (K20) | 0,6 (0-300°C) |

Transformation temperature Tg [°C] | 525 | 557 | 670 | n.a. |

Refractive index ne (546,1 nm) | 1,5 | 1,5 | 1,6 | 1,5 |

Abbe coefficient ve | 65,4 | 63,7 | 55,9 | 67,6 |

E-Modul E [103 N/mm2] | 64 | 82 | 90 | 73 |

Knoop hardness HK0,1/20 | 480 | 610 | 620 | 522 |

Note: The property values given are approximate values.

Borosilicate glass

The name of this technical glass type comes from the two main components silicon dioxide as well as botrioxide. Components made of this glass are characterized by a very low coefficient of expansion and excellent temperature resistance. In addition, borosilicate glass has a high chemical resistance. Especially Borofloat® 33 (SCHOTT AG) is very resistant to acids, alkalis and other liquids. In addition, the glass offers low intrinsic fluorescence and high transparency in the visible and near IR / UV range.

SCHOTT NBK-7®

It is a commonly used optical glass, more precisely a chemically stable borosilicate crown glass (SCHOTT AG). It is often used for high-quality optics and prisms because it contains very few bubbles or inclusions. Due to its high coefficient of expansion, it is more sensitive to thermal fluctuations than quartz glass, for example.

Zerodur®

Zerodur is an optical glass-ceramic that is particularly known for its very low coefficient of thermal expansion (SCHOTT AG). This material is therefore particularly suitable for applications within aerospace or laser technology, where the component geometry is to be maintained despite high temperature fluctuations.

Fused silica

Fused silica consists of silicon oxide. Due to its very high purity, it is one of the most commonly used glasses for optical applications. In addition, this material is well suited for complex shaping and polishing with very tight tolerances. The property values given are based on the example of Corning® HPFS® 7979, 7980, 8655 (CORNING, Inc.)