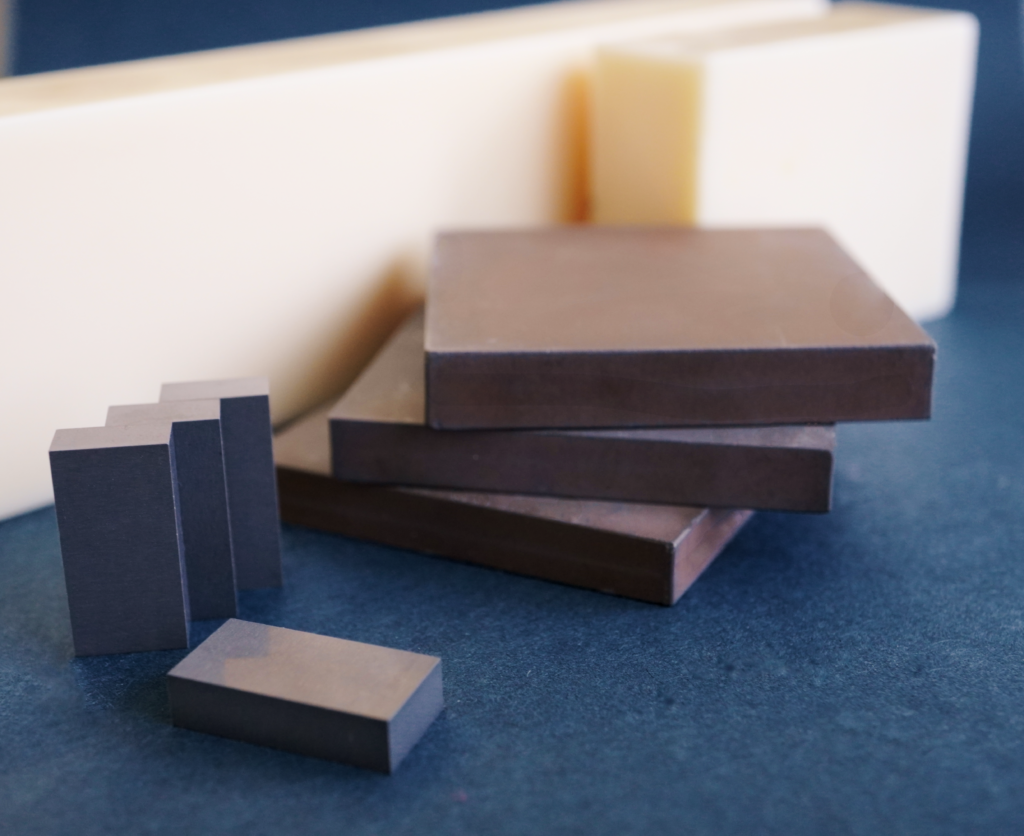

Technical ceramics

Technical ceramics, also known as advanced ceramics were first used as electrical insulators in the mid-19th century. Since then, this material has been sourced for a wide range of applications. Technical ceramics acquire most of their properties through a sintering process.

The following describes the common types with regard to ceramic machining.

If you should desire another ceramic material, then please send us a Request.

Material properties

| Properties | Al2O3 | SiC | Si3N4 | ZrO2 |

|---|---|---|---|---|

Density p [g/cm3] | 3,9 | 3,2 | 3,3 | 5,6 |

Coefficient of expansion a (20°C – 500°C) [1*10-6/K] | 7,3 | 3,7 (40-400°C) | 2,8 (40-400°C) | 10,4 |

Max. Operating temperature [°C] | 1950 | 1400-1750 | 1600 | 1700 |

Flexural strength [MPa] | 350 | 450 | 1020 | 400 |

Compressive strength [MPa] | 3500 | n.a. | n.a. | 2000 |

E-Modul E [103 N/mm2] | 380 | 440 | 300 | 200 |

Vickers hardness HV1 | 1760 | 2345 | 1428 | 1400 |

Note: The property values given are approximate values.

Alumina (Al2O3)

Alumina is the most commonly used technical ceramic material. It has a variety of useful properties, such as high corrosion resistance, hardness, and thermal / electrical insulation. The material is available in a range of purities, allowing it to be used in many different industries.

Silicon carbide (SiC)

Silicon carbide is taking on an increasing role for machined components with tight tolerances. This material has a very high strength and hardness, despite a low weight. Depending on the manufacturing technique, the type and proportion of composition of this type of ceramic varies.

Silicon nitride (Si3N4)

Similar to silicon carbide, silicon nitride is a very hard and wear-resistant material. Very good thermal insulation and high strength make this material special.

Zirconia (ZrO2)

Zirconia is also available in many different forms, designed for a wide variety of applications. By adding various metal oxides, certain properties of this type of ceramic can be stabilized at room temperature. Examples of variants are yttria- or magnesia-partially stabilized zirconia.